Blog

Helpful Information About Potential Welding Careers & Trucking Jobs

-

A Beginner’s Fast-Track Guide

The U.S. job market needs more new welders, cutters, solderers, and brazers annually. Welding certifications open doors to stable careers with solid earning potential. According the Bureau of Labor Statistics, welders in the United States earn a median annual salary of $51,000. Those with specialized skills and certifications can command much more. Rig welders, for instance, can earn up to $95 per hour. This makes welding certification California programs smart investment for career changers. Most graduates start at approximately $20 per hour with full benefits, and their pay increases steadily with experience and additional certifications. Fast-track programs can help students become certified and job-ready in less than a year. Employment opportunities continue to grow, with total national employment for welders projected to exceed 457,000 by 2032. This guide explains how to start a welding career in California through the most practical path.Key Takeaways

California offers a clear pathway to welding certification that can lead to stable, well-paying careers with strong job growth prospects.- Complete a high school diploma or GED to enroll in training

- California has no state welding license but recognize industry certifications like AWS D1.1, ASME IX, and API 1104

- Entry-level welders in California generally start at an annual salary of $51,000

Understand the Basics of Welding Certification in California

Understanding welding certification matters before you can start a welding career in California. The certification process for welders works differently than other trades in the Golden State.What is a welding certification?

Welding certification proves that you can produce sound welds that meet specific industry standards. This credential shows the welding process, materials, and positions where you’ve demonstrated skill. Whether you work with structural steel, pipe, or specialty applications, certification validates your abilities to potential employers. The certification covers specific process like:- Shielded Metal Arc Welding (SMAW)

- Flux-Cored Arc Welding (FCAW)

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

Why California has no state-issued welder license

California doesn’t issue a single state welder license for employment. The state relies on industry-recognized certifications to validate welders’ skills. Employers and building officials accept certifications based on specific welding codes relevant to their projects. California does require contractors who perform welding operations commercial to get a C-60 Welding Contractor License through the California Contractors State License Board (CSLB). This license applies to businesses, not individual welders.Common Welding Codes

There are three primary welding codes that are recognized throughout California:- AWS D1.1 – This governs structural steel welding and is essential for work on buildings, bridges, and other structural applications.

- ASME Section IX – Applies to pressure vessels and components, governing most qualifications under an Authorized Inspector.

- API 1104 – Developed specifically for oil and gas pipelines, crucial for pipeline welders.

Steps to Get Certified as a Welder in California

Getting certified as a welder in California requires four main steps. Each step gets you closer to credentials that employers recognize and value.1. Have a high school diploma or GED

Start with a high school diploma or GED. Most training programs and apprenticeships throughout California require this basic educational qualification. While welders in California aren’t legally required to have a diploma to work, those without one often struggle to qualify for many trade programs or job opportunities. Employers look for candidates with this baseline education since it shows critical thinking abilities and discipline.2. Enroll in a welding training program

Next, you need formal training. California offers several paths” Trade schools like Advanced Career Institute provide programs lasting 9-10 months where students learn four primary welding types:- Gas metal arc welding

- Shielding metal arc welding

- Gas tungsten arc welding

- Flux-cored arc welding

3. Choose your welding process ad test type

Your certification path depends on where you want to work. Options include structural steel, petroleum pipelines, sheet metal, or chemical refinery welding industries. Common tests will follow the standard welding codes that we mentioned earlier regarding:- structural steel

- pressure vessels

- oil and gas pipelines

4. Pass a performance test at an accredited facility

The final step involves passing a performance-based test at an AWS. Accredited Testing Facility (ATF). During this test, you demonstrate their abilities by depositing a sound weld inspected by an AWS Certified Welding Inspector. Test prices range from $499 to $899, plus AWS application fees. Once you pass, you receive transferable credentials recognized throughout the industry. No prerequisite certifications are required – if you can perform the weld successfully, you qualify.Welder Training Programs Explained

Aspiring welders in California can choose between different training paths. Each option has distinct advantages based on your situation and career goals.How long does it take to become a certified welder?

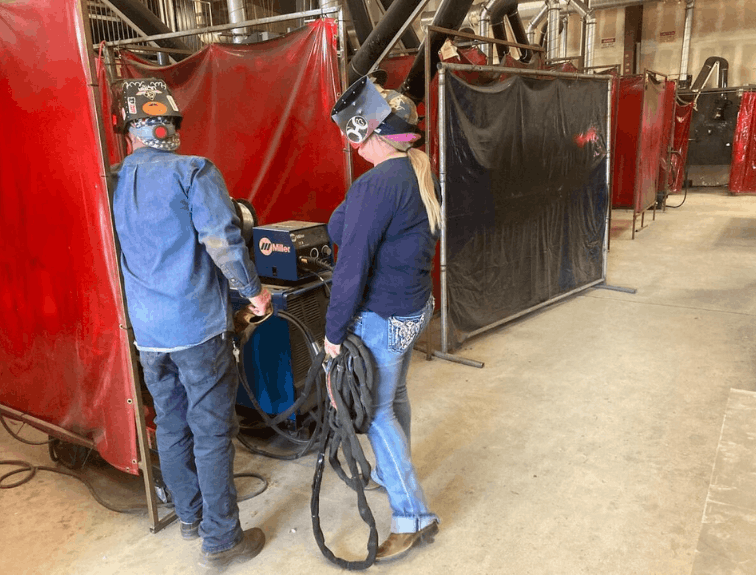

Fast-track programs at institutions like Advanced Career Institute can be completed in less than a year. Some colleges offer certifications through 5-week course segments.What to expect in hands-on programs

Programs focus on practical application alongside theory. Students learn multiple welding process, including:- SMAW (stick)

- GMAW (MIG)

- GTAW (TIG)

- FCAW (flux-core)

What Jobs Can I Get as a Welder?

Once you earn certifications, welders in California can find opportunities across multiple industries with solid pay scales and room for advancement.Entry-level welding jobs and average salaries

Entry-level certified welders typically start in positions as:- Welder

- Fabrication welder

- Welder fitter

- Wirer

Industries hiring certified welders in California

Certified welders can find work in numerous sectors throughout the state:- Oil refineries and pipeline construction

- Nuclear power plants and power generation

- Aerospace and manufacturing

- Structural building and bridge construction

- Automotive industry

- Commercial fabricating jobs

Advanced roles and specialization options

Experienced welders have several paths for career advancement:- Certified welding inspector (CWI)

- Quality control inspector

- Welding project manager

- Welding shop supervisor

- Welding sales representative

- Welding shop owner

Maintaining certification and continuity logs

Welders must document continuous practice through continuity logs to keep their certification valid. For AWS D1.1 structural steel certification (using SMAQ, FCAW, or GMAW) welders must prove continuous welding without breaks exceeding 6 months. Sheet metal welders certified under AWS D9.1 (using GTAW or GMAW) must document continuous practice without breaks exceeding 12 months. Failure to maintain continuity requires recertification, costing approximately $500 per process. Most employers and unions maintain records for their welders. Self-employed welders must track their own continuity documentation. Welding certification offers a practical path to stable, well-paying careers in California. This guide covers the key steps: California relies on industry-recognized certifications like AWS D1.1, ASME IX, and API 1104 rather than state licenses. These certifications prove your skills with specific welding processes and positions. The certification process starts with a high school diploma or GED. Then you choose between trade schools (as short as 9 months) or a longer apprenticeship. Fast-track programs work well for people ready to start working quickly. You pick your welding process based on your career goals, then pass performance tests at accredited facilities. The money makes sense. Entry-level positions start around $20 per hour with benefits. Experienced welders with specialized skills earn much more. The industry offers advancement opportunities across oil and gas, aerospace, manufacturing, and construction sectors. Welding certification opens doors to career stability and growth. The projected national employment exceeding 437,000 welders by 2032 shows strong demand for skilled workers. People considering this career path can expect their training investment to pay off long-term. Welding offers immediate job opportunities plus room for professional growth through additional certifications and specializations.

FAQs

How long does it typically take to become certified welder in California?

The duration can vary, but fast-track programs at trade schools can be completed in as little as 9 months.Is a state-issued welding license required to work as a welder in California?

No, California does not issue a state welding license. Instead, the state relies on industry-recognized certifications to validate welder skills.What are the common welding certifications recognized in California?

The three primary welding codes widely recognized in California are:- AWS D1.1 – for structural steel welding

- ASME Section IX – for pressure vessels

- API 1104 – for oil and gas pipelines

What is the average salary for certified welders in California?

The average salary for entry-level welders in California is $21 an hour with benefits, while experienced professionals can earn significantly more.How do I maintain my welding certification in California?

To maintain certification validity, welders must document continuous practice through continuity logs. They need to show proof of continuous work without breaks exceeding 6 months. Apply for Welding Training Now. Fast-track to certification in less than a year. -

Learn What Industries Offer Opportunities for a Successful Welding Career

Welding is a critical skill that supports a wide range of industries, from construction and manufacturing to aerospace and energy. Without skilled welders, essential structures, machinery, and transportation systems wouldn’t be possible. As industries continue to grow and evolve, the demand for trained welders remains strong, offering countless career opportunities for those with the right skills. In this blog, we’ll explore the industries that rely on welders, highlighting the vital role they play and the exciting career paths available in this essential trade.Why Welding Is an Essential Skill Across Industries

Welding jobs are a fundamental trade that serves as the backbone of countless industries, making it one of the most versatile and in-demand skills in the workforce. From towering skyscrapers and massive bridges to intricate aerospace components and high-performance vehicles, welding is responsible for creating and maintaining the structures and equipment that keep the world moving. Beyond construction and manufacturing, welders play a crucial role in emerging industries like renewable energy and advanced technology, ensuring innovation and progress continue. With advancements in automation and specialized welding techniques, the need for skilled welders is only growing, offering job security and career advancement opportunities across a variety of fields.Industries That Rely on Welders

1. Construction and Infrastructure

The construction industry depends heavily on welders to create and maintain buildings, bridges, and other essential infrastructure. Welders work on steel frameworks, reinforce concrete structures, and ensure the stability of high-rise buildings. Public infrastructure, such as highways, tunnels, and pipelines, also requires skilled welders to maintain and repair metal components. As cities expand and new projects develop, welders remain at the forefront of this industry.2. Manufacturing and Fabrication

Manufacturing is one of the largest industries for welders, offering employment in factories that produce everything from household appliances to industrial machinery. Welders work with metal components to assemble products, reinforce materials, and ensure durability. Many modern manufacturing facilities use automated welding processes, but skilled welders are still needed to oversee production, inspect welds, and handle intricate tasks that machines cannot perform.3. Automotive and Transportation

Welders play a significant role in the automotive industry, helping to build and repair cars, trucks, and even public transportation systems like buses and trains. Every vehicle contains welded components that contribute to its safety and efficiency. Welders also work on custom automotive projects, such as race cars and specialty vehicles, creating high-performance frames and exhaust systems. With the rise of electric and autonomous vehicles, the demand for specialized welding skills in this field is increasing.4. Aerospace and Aviation

Precision welding is crucial in the aerospace industry, where aircraft and spacecraft require strong, lightweight, and durable materials. Aerospace welders work on airplane fuselages, jet engines, and satellite components, using advanced techniques like TIG welding and laser welding to ensure structural integrity. The high standards and safety regulations in aerospace welding make this a challenging but rewarding career path.5. Shipbuilding and Maritime Industry

The maritime industry depends on welders to build and repair ships, submarines, and offshore drilling platforms. These structures must withstand extreme weather conditions and the constant wear of saltwater exposure. Some welders in this field specialize in underwater welding, a highly skilled and high-paying profession that involves working in submerged environments to repair ship hulls, pipelines, and offshore structures.6. Energy and Power Generation

Welding is essential in the energy sector, helping to construct and maintain pipelines, power plants, and renewable energy systems. In the oil and gas industry, pipeline welders work in challenging environments to ensure the safe transportation of fuel. Meanwhile, the renewable energy sector relies on welders to build wind turbine towers, solar panel structures, and hydroelectric power facilities. As the world shifts toward sustainable energy, welders will continue to play a crucial role in shaping the future of power generation.7. Agriculture and Heavy Equipment

Farms and agricultural businesses rely on welders to repair and maintain heavy machinery, including tractors, plows, and irrigation systems. Welding is used to build sturdy equipment that can endure rough conditions and heavy use. Skilled welders in this industry ensure that farmers and construction workers have the durable tools they need to operate efficiently.8. Military and Defense

The military relies on welders to build and maintain vehicles, ships, aircraft, and infrastructure used in national defense. Military welders may work on armored vehicles, aircraft carriers, or even weapons systems, ensuring they meet strict durability and performance standards. Some welders in this industry work directly for government agencies, while others are employed by defense contractors.How to Get Started in Welding for These Industries

For those interested in a welding career, proper training and certifications are essential. Many industries require specialized welding skills, so gaining hands-on experience and obtaining certifications from organizations can open doors to high-paying opportunities. Enrolling in a welding training program, such as the one offered at Advanced Career Institute, can help aspiring welders build a strong foundation and gain the technical knowledge needed to succeed in various industries.Why Welding Is a Strong Career Choice

Welding jobs offer security, career advancement, and excellent earning potential. As industries continue to expand and evolve, the demand for skilled welders remains steady. Whether working on massive infrastructure projects, high-tech aerospace components, or cutting-edge renewable energy systems, welders have the opportunity to build a fulfilling career in a field that keeps the world running. From construction and manufacturing to aerospace and energy, skilled welders are needed in nearly every industry. Welding jobs provide stability, diverse career paths, and opportunities for professional growth. If you're considering a hands-on career with strong earning potential, welding could be the perfect choice for you.Start your welding journey today with Advanced Career Institute and gain the skills needed to work in these essential industries!

-

How to Become a More Efficient Welder

Whether you’re an experienced welder or just graduated from welding training, there are standard welding practices every welder should follow. Along with this, welders should be aware of common mistakes across the industry. Read more about some of the most common welding mistakes within the industry and how you can avoid them in the future.Lack of Preparation

Lack of preparation in any industry is unprofessional and should not be taken lightly when prepping to weld. Thoroughly preparing the metal you will be welding to remove any paint, rust, dirt, and other foreign substances is vital in ensuring the surfaces are clean. Failure to do so could lead to a weak weld on the pieces of metal. Cleaning isn’t the only major thing you should prep for before welding. Knowing the type of metal and its measurements is important in knowing how to weld the pieces together and if they will need multiple passes. Knowing the measurements of the specific metal types you are welding and adequately cleaning them will help you better prepare before welding. This knowledge will also help you determine a plan of action for how to execute the welds. Many of the other common welding mistakes stem from a lack of preparation.Safety Precautions

Safety is the top priority in welding and almost every occupation today. Working with flammable gases, sharp metal, debris, and a torch daily presents welders with a lot of liability. Making sure you know the proper safety precautions before diving into a weld can prevent accidents and even be lifesaving. To begin with, some of the most common precautions are personal protective equipment (PPE) pieces. These include work boots (preferably steel-toe), hearing protection, welding shield/helmet, and safety glasses. Ensuring you have the basic safety requirements is always an easy place to start when taking proper safety precautions. Your preparation before welding will help with safety too! Since you have prepared for what you are welding, you will know the appropriate types of welds needed for the job. Preparation goes a lot farther than just knowing what you will be welding.Wire and Electrode Selection

Before welding, it is essential to choose the correct wiring and electrodes needed for the job. This is regardless of the type of welding you will be doing (the three most popular are stick, flux-core, and MIG). Electrodes and wires are suited for different welding applications and need specific types to be effective. Knowing which types work with the different welds you are performing can save you from re-doing any wrong ones.Interpass and Preheat Temperatures

Like many common appliances and machinery, welding machines must be preheated before using them. Failure to preheat your machine and the metal area surrounding the weld to the proper temperature before conducting the weld can lead to problems and create more work for yourself. Proper preheating leads to fewer cracks and helps prevent future issues with the weld. Choosing the correct interpass temperature will help to solidify and correctly conduct your weld between the metals. Knowing what temperature is needed for the thickness and type of metal you are welding will help your weld and your preparation. Having correct preheat and interpass temperatures can save you from having to re-do a weld and other headaches that may result. Proper welding training can be a huge step in becoming a successful welder and avoiding these common welding mistakes. You will learn the proper preparation and techniques to weld various metals correctly. Qualified students can apply for tuition assistance programs and work with our job placement team to find openings with local and national employers! Get started in your welding career today! Call our admissions team at 866-951-4821 to learn more about enrolling with ACI! -

Which campus works for you?

Advanced Career Institute has been in business for over 30 years. We have grown to five campuses that provide students in California and Nevada with the best training as they work toward getting their CDLs and welding certifications. Learn about each of our campuses and find the perfect one for your needs.Visalia CDL Training and Welding Training

The ACI Visalia campus is our oldest campus, having been open since 1993. However, it has recently moved to a new state-of-the-art facility in 2022. The new Visalia campus is located at 1243 N Clancy St, Visalia, CA 9329, and offers students both CDL and welding training courses. The complete list of the courses provided at Visalia is Class A CDL training, Advanced Class A CDL training, CDL refresher training, Agricultural Transportation training, and advanced welding training. The new Visalia campus provides students access to the four-acre truck driving yard and our 5,000 sq. ft. welding lab.Fresno CDL and Welding Training

Our Fresno campus, located at 2953 S. East Avenue, Fresno, California 93725, was the second campus we opened in July 2000. When we opened our Fresno campus, welding also joined our programs list. As of 2022, the programs offered at our Fresno campus are Class A CDL training, Advanced Class A CDL training, Agricultural Transportation training, and Advanced Welding training.Merced CDL Training

Due to increased student demand, we opened our Merced campus in March of 2015. Our Merced campus is at 1741 Ashby Rd, Suite B, Merced, CA 95348. The Merced campus offers Class A CDL training, Advanced Class A CDL training, CDL refresher training, and Agricultural Transportation training. Merced helps us reach all students in the Valley and give them the best Commercial truck driver training possible.Bakersfield CDL and Welding Training

ACI Bakersfield is one of three campuses offering both CDL training and welding courses. Our Bakersfield campus is located at 2925 Mosasco St., Unit B, Bakersfield, CA 93312, and has been open since 2018. Our CDL training programs include our Class A CDL training, Agriculture Transportation training, Advanced Class A CDL training, and a CDL refresher course. Our Bakersfield campus also offers ACI’s advanced welding training, our 38-week welding certification course.Las Vegas CDL Training

In 2020 we opened the ACI Las Vegas campus using our over 30 years of knowledge in the trucking industry to provide the best training in the North Las Vegas area for our students. We opened our Las Vegas campus at 4020 E Lone Mountain Rd Suite 100 North Las Vegas, NV 89081; it became our fifth campus. The Las Vegas campus offers Class A CDL training, Advanced Class A CDL training, CDL refresher training, and Agricultural Transportation training. Students that attend our Las Vegas will have access to our four-acre paved training yard and new upgraded classrooms.Come to ACI to be trained by the best staff in California! Contact us today to reserve your seat at one of our campuses.

-

Welcome to our new California Welding and CDL Training Facility

Big news at ACI! We have officially moved into our newly built Visalia campus! Our new campus is located at 1243 N Clancy St. Visalia, CA 93291. Our upgraded facility has improved CDL training and welding facilities, allowing students to further their careers in a new state-of-the-art learning environment.CDL Training at our Visalia, CA Campus

Our CDL training facilities have grown! Our 4-acre training yard is freshly paved and painted. Our students have plenty of room to practice all backing maneuvers and get comfortable operating a commercial vehicle. Our new driving range allows 7 to 8 trucks on the yard at once, with multiple students simultaneously practicing different parts of training. ACI’s new Visalia campus has dedicated spaces to practice pre-trip inspections, different driving techniques, and classrooms for students to study. These classrooms have been upgraded with the latest education technologies to allow students a modern learning environment. We have also added a new covered, outdoor lunch area when students are ready for a much-deserved break. We are ecstatic about the opening of our new campus, and can now train anywhere between 75 and 85 students at any given time.

Welding Training at ACI’s Visalia Campus

Students are given a warm welcome to the brand-new welding lab at our Visalia Campus. The state-of-the-art welding lab is 5,000 sq ft. Welding students have dedicated areas to practice the various welding techniques required to receive their American Welding Society certification. Our new space has increased ventilation and private welding bays for each student to focus individually on mastering their craft. Same as our CDL students, welding students also have access to our upgraded classrooms and have a dedicated space to learn about blueprint reading, construction math, and site/shop safety. With ACI’s new welding lab and our four-class schedules, there can be 100 welding students at our facility on any given day!

Student-centered Improvements

Students' success is important to us at ACI, and our new Visalia campus has our student's success at its core. Students can expect an improved experience from start to finish. We have upgraded our front office spaces so that new and current students can quickly and easily find the help they need. Our admissions staff have private offices to help you find your perfect training path and our job placement team has a dedicated space to help you find the perfect job after graduation from Advanced Career Institute. Student lounges and a spacious kitchen area give students a space to relax and feel at home while training at ACI.

Are you ready to experience all that our new Visalia campus can offer? If so, contact us today at 877-649-9614 to get started!

Are you ready to experience all that our new Visalia campus can offer? If so, contact us today at 877-649-9614 to get started!

-

Show Your Appreciation For Our Road Heroes!

For many, the holiday season drums up memories of large food spreads, festive decorations adorning businesses and homes alike, and unwrapping gifts of all sizes. But have you ever stopped to think about how those items arrived in your hands just in time for your special celebration? Professional truck drivers play a large part in that process. They transport goods from turkeys to holiday trees and everything in between. These men and women sacrifice spending this special time with their loved ones to ensure our gatherings go off without a hitch. Now more than ever, it's important to show them how thankful we are for their service. Keep reading to see different ways you can thank a professional driver during this time of giving!Thank A Driver with a Home Cooked Meal

Drivers have limited home-cooked meal options while on the road, meaning they often eat typical truck stop snacks or fast-food items. To show appreciation for the hard work they are providing this season, you can opt to share your own turkey spread! Alternatively, there are many organizations, such as Meals for 18 Wheels, where you can volunteer to deliver ready-made meals to drivers. Whichever you choose may seem like a small sentiment, but truck drivers will for sure be very grateful!Show Thanks by Picking Up the Check

If your celebrations happen at a restaurant or diner, check if any drivers are also enjoying a meal. If so, you can offer to cover their bill. You could even invite them to join in your festivities, as many of them are away from their own celebrations and traditions. Truck drivers can provide great company and interesting conversations, as they encounter something new every day that they're driving across the country. And to think, all of that could begin with a small kind gesture of gratitude!Spread Holiday Cheer with Thank-You Themed Goody Bags

A great way to get the whole family involved is to set up a goody bag creation station to pass out to drivers you encounter throughout the season. The bags can be filled with travel-size essential items, grab-and-go snacks, or holiday-themed décor they can use to spruce up their trucks. You might also want to include a themed greeting card that everyone can sign. The best part – these items can be purchased at your local dollar store! Once all the bags are filled, make sure to keep them somewhere that can be easily accessed to hand out, such as your car. This inexpensive gift idea can have the biggest impact on a driver’s day!Post on Social Media Using the #ThankATrucker Hashtag

Social media has become a very popular way for drivers to keep in touch with their family and friends. This gives you the perfect opportunity to show your thankfulness to drivers, and best of all – it's free to do! Before you post, make sure to include the hashtag #ThankATrucker so your message can reach even more drivers than you thought possible! You can also repost messages from others who are using the hashtag to spread their positive sentiments. Lastly, you can ask your friends or followers to also create a caption with the hashtag and help spread good messages to all drivers!Truck Drivers Thank Advanced Career Institute

While everyone is thanking our heroes of the road, truck drivers are also showing their gratitude to those who helped them get where they are today. Advanced Career Institute has received many heartfelt messages of thanks and appreciation from our graduates who underwent our CDL training program and have gone on to create successful and lucrative driving careers with our trucking partners. Many graduates share their stories with us online, but some make sure to stop by their campus in person. Drivers also make sure to stop by our Job Placement program offices to pass along their gratitude to those who helped get the ball rolling toward their new careers.Let ACI help you begin your new driving career! Fill out the form on this page or give us a call at 866-218-7968 to get your spot reserved in our next class!