Underwater welding is a dangerous career yet it employs numerous people. Why is this so? Read on to learn more about the pros and cons of underwater welding.

What is Underwater Welding & How Does It Work?

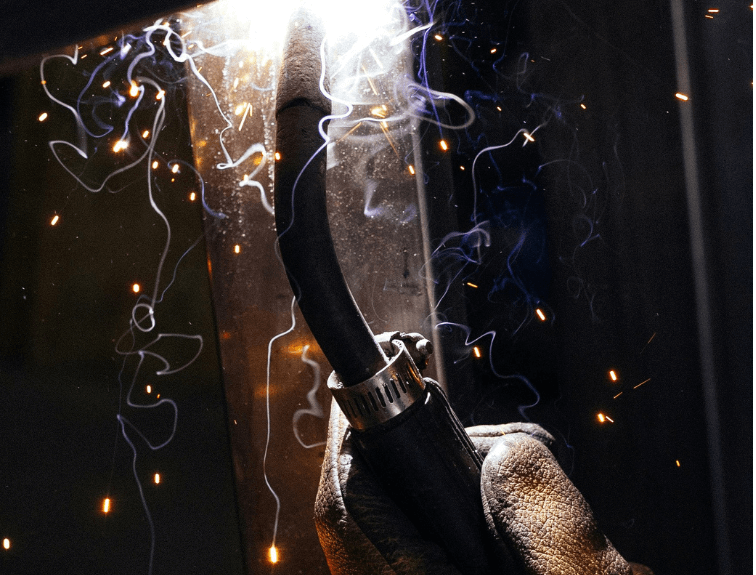

Underwater welding has been around since 1932, and is often referred to as hyperbaric welding. It can take place in wet or dry environments. Wet welding is when the welder is entirely submerged in water. The welding is executed using forms of arc welding that employ a waterproof electrode where the welding supply connects to equipment through cables and hoses. Conversely, dry welding is used for high integrity welds. During dry welding, the weld is completed within a sealed pressure chamber that prevents water from entering the work area. They often use a form of gas tungsten arc welding. Dry welding is often used to repair pipelines and ships. Underwater welding research is being conducted at depths of up to 3,300 feet.

Why is it dangerous?

My guess is that your first thought about underwater welding was “Electricity and water aren’t a good mix. Isn’t that dangerous?” The answer is…yes! However, many safety precautions are taken to reduce the risk. Underwater welding is completed using a welding stick where a layer of bubbles is created to shield the weld from water. Dry welding is also a safer method since the weld itself is not exposed to water. However, electricity does not pose the biggest threat. Welders operate at high pressures that threaten the body. Additionally, large bubbles created by the weld and the overall dark atmosphere underwater makes it hard to see, and is threatening to the welder.

The most notable underwater risk is differential pressure or Delta P. In Delta P, water from one area attempts to rush to fill another. The pressure difference accumulates hundreds of pounds which can draw divers in and make it very hard to escape. Although there is a high risk of Delta P, companies have come up with action plans on how to avoid this fatal occurrence. For more information on Delta P, check out this video.

Why do people choose to take these risks?

Many welders choose this career path because it is exciting, peculiar and challenging. Additionally, underwater welders are essential components to industries all over the world. This means that skilled welders are in high demand. Currently, companies do not possess the technology to complete underwater welding tasks without humans. This provides underwater welders with job security. On top of it all, underwater welders have the opportunity to make significant salaries that they would not have access to as a typical welder.

The Future of Underwater Welding

According to the Bureau of Labor Statistics, the average salary for an underwater welder is around $53,990 per year or $25.96 per hour. Underwater welder jobs are concentrated in California, Florida, Michigan and Washington. Your career can take place in one of two locations: inland or offshore. Inland welders typically make less than their offshore colleagues. They tend to work on bridges, dams and small water vessels. Although there is less pay involved, you operate on a less demanding schedule (40-hour work weeks) and less travel is required. However, offshore welders tend to bring in the big bucks. They work on oil rigs and large ships. In this job, you may spend a significant time out at sea and can expect to long work weeks, even up to 80 hours!

Interested in becoming an underwater welder? The first step is to get your welding certification. Advanced Career Institute offers hands-on welder training in the California area. ACI welding campuses are located in Visalia and Fresno. For more information, head over to Welder Training!