Whether you’re an experienced welder or just graduated from welding training, there are standard welding practices every welder should follow. Along with this, welders should be aware of common mistakes across the industry. Read more about some of the most common welding mistakes within the industry and how you can avoid them in the future.

Lack of Preparation

Lack of preparation in any industry is unprofessional and should not be taken lightly when prepping to weld. Thoroughly preparing the metal you will be welding to remove any paint, rust, dirt, and other foreign substances is vital in ensuring the surfaces are clean. Failure to do so could lead to a weak weld on the pieces of metal.

Cleaning isn’t the only major thing you should prep for before welding. Knowing the type of metal and its measurements is important in knowing how to weld the pieces together and if they will need multiple passes. Knowing the measurements of the specific metal types you are welding and adequately cleaning them will help you better prepare before welding. This knowledge will also help you determine a plan of action for how to execute the welds. Many of the other common welding mistakes stem from a lack of preparation.

Safety Precautions

Safety is the top priority in welding and almost every occupation today. Working with flammable gases, sharp metal, debris, and a torch daily presents welders with a lot of liability. Making sure you know the proper safety precautions before diving into a weld can prevent accidents and even be lifesaving.

To begin with, some of the most common precautions are personal protective equipment (PPE) pieces. These include work boots (preferably steel-toe), hearing protection, welding shield/helmet, and safety glasses. Ensuring you have the basic safety requirements is always an easy place to start when taking proper safety precautions. Your preparation before welding will help with safety too! Since you have prepared for what you are welding, you will know the appropriate types of welds needed for the job. Preparation goes a lot farther than just knowing what you will be welding.

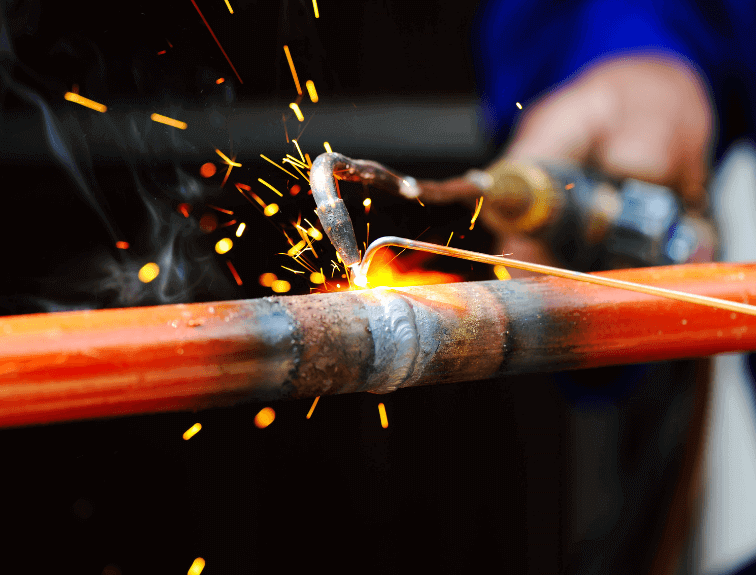

Wire and Electrode Selection

Before welding, it is essential to choose the correct wiring and electrodes needed for the job. This is regardless of the type of welding you will be doing (the three most popular are stick, flux-core, and MIG). Electrodes and wires are suited for different welding applications and need specific types to be effective. Knowing which types work with the different welds you are performing can save you from re-doing any wrong ones.

Interpass and Preheat Temperatures

Like many common appliances and machinery, welding machines must be preheated before using them. Failure to preheat your machine and the metal area surrounding the weld to the proper temperature before conducting the weld can lead to problems and create more work for yourself. Proper preheating leads to fewer cracks and helps prevent future issues with the weld.

Choosing the correct interpass temperature will help to solidify and correctly conduct your weld between the metals. Knowing what temperature is needed for the thickness and type of metal you are welding will help your weld and your preparation. Having correct preheat and interpass temperatures can save you from having to re-do a weld and other headaches that may result.

Proper welding training can be a huge step in becoming a successful welder and avoiding these common welding mistakes. You will learn the proper preparation and techniques to weld various metals correctly. Qualified students can apply for tuition assistance programs and work with our job placement team to find openings with local and national employers!

Get started in your welding career today! Call our admissions team at 866-951-4821 to learn more about enrolling with ACI!